Understanding the VFD wiring diagram is crucial for anyone working with variable frequency drives. This diagram serves as the blueprint for connecting a VFD to your motor and power supply, ensuring safe and efficient operation. A correctly followed VFD wiring diagram prevents costly mistakes and potential damage to equipment.

What is a VFD Wiring Diagram and How is it Used?

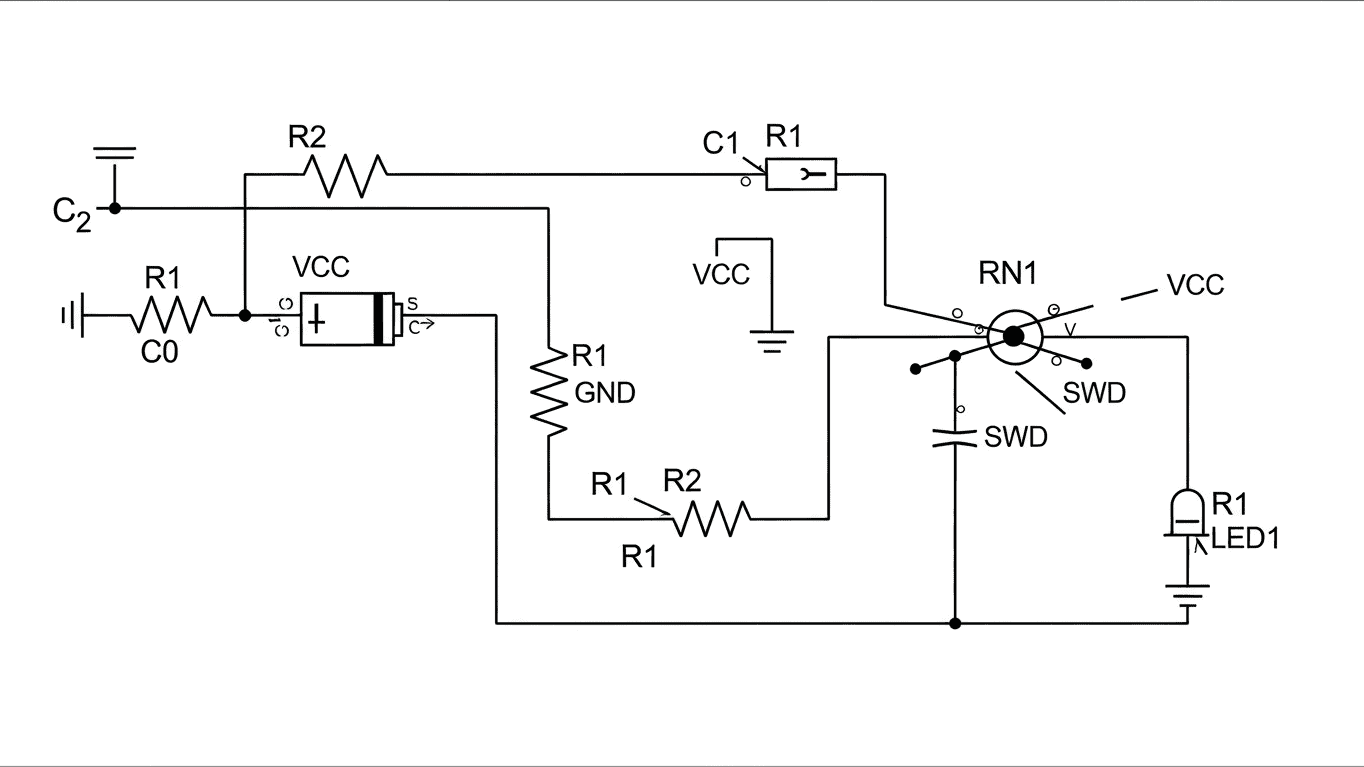

A VFD wiring diagram is a schematic representation that illustrates the electrical connections required for a variable frequency drive. It details where to connect the incoming power (typically three-phase or single-phase AC power), how to wire the motor to the VFD's output terminals, and often includes connections for control signals like start/stop commands, speed adjustments, and fault indications. These diagrams are indispensable for electricians and technicians performing installations, maintenance, or troubleshooting. The importance of a VFD wiring diagram cannot be overstated; it's the primary tool for ensuring a safe, reliable, and functional system.

VFDs are used to control the speed of AC electric motors. By varying the frequency and voltage supplied to the motor, a VFD can precisely adjust its speed and torque. This offers significant advantages over traditional methods of motor speed control, such as mechanical gearboxes or rheostats. The wiring diagram guides the user through the specific connections needed to achieve this control. For instance, it will clearly show:

- Power input terminals (L1, L2, L3 or Line 1, Line 2, etc.)

- Motor output terminals (T1, T2, T3 or U, V, W)

- Grounding points

- Control input/output terminals for external devices

Different types of VFDs and applications will have variations in their wiring diagrams. A simple VFD for a single motor will be less complex than a VFD used in an automated process with multiple sensors and control inputs. Here's a simplified look at common wiring sections:

| Connection Type | Typical Terminals | Purpose |

|---|---|---|

| Power Input | L1, L2, L3 (or 1, 2, 3) | Connects to the incoming AC power supply. |

| Motor Output | T1, T2, T3 (or U, V, W) | Connects to the motor windings for variable speed control. |

| Control Inputs | DI (Digital Inputs), AI (Analog Inputs) | Receives commands for start/stop, speed adjustment, etc. |

| Control Outputs | RO (Relay Outputs), AO (Analog Outputs) | Provides feedback on VFD status (e.g., running, fault). |

When referring to a VFD wiring diagram, it's essential to identify the specific model of the VFD you are working with, as manufacturers often have unique terminal designations and wiring configurations. Always consult the manufacturer's documentation for the most accurate and up-to-date VFD wiring diagram specific to your unit. This ensures that all connections are made according to safety standards and the VFD's intended operational parameters.

For detailed information and precise instructions on connecting your specific VFD model, please refer to the documentation provided with your VFD. It will contain the most accurate and essential VFD wiring diagram for your installation.