A Well Pump Wiring Diagram is an essential guide for anyone dealing with a well water system. This diagram provides a visual representation of how all the electrical components of your well pump system are connected. Understanding a Well Pump Wiring Diagram is crucial for troubleshooting, maintenance, and ensuring the safe and efficient operation of your water supply.

What is a Well Pump Wiring Diagram and How Is It Used?

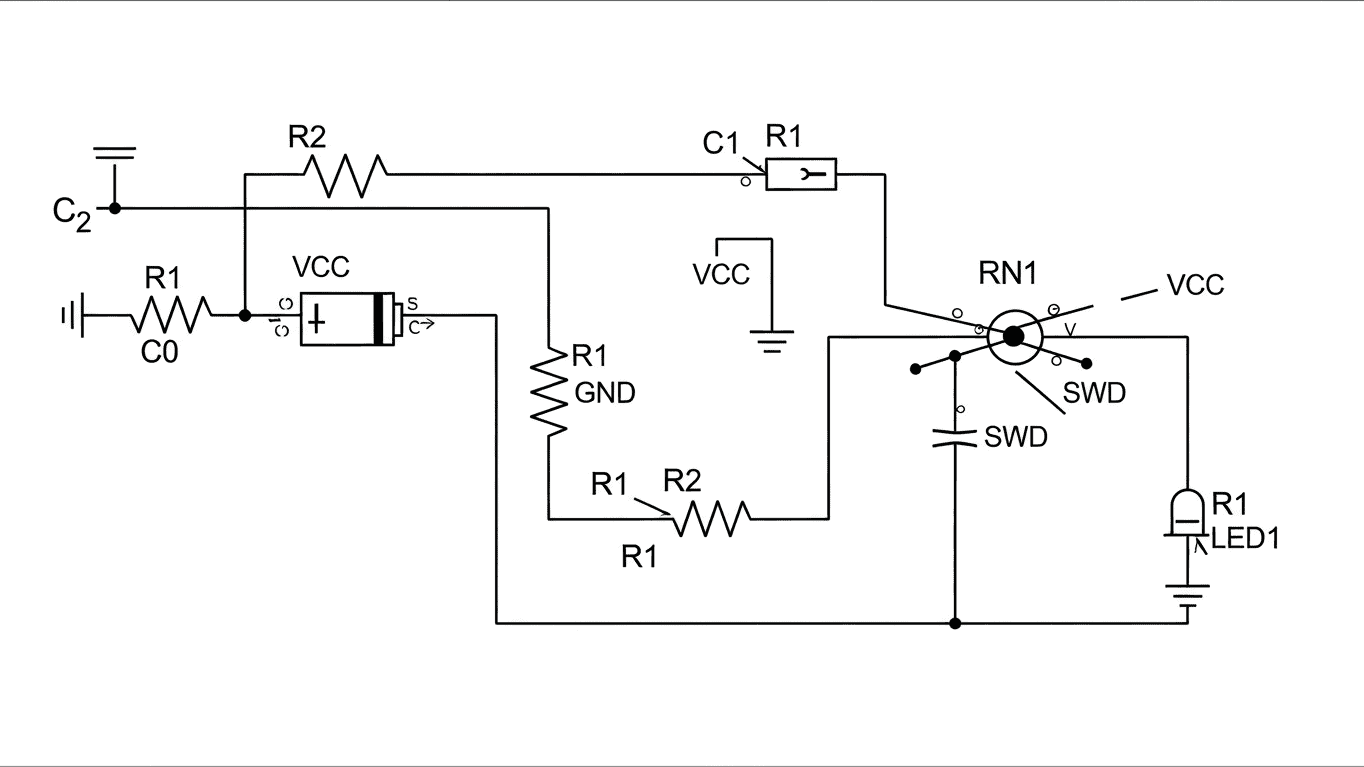

At its core, a Well Pump Wiring Diagram is a schematic that illustrates the electrical pathways within your well system. It shows how the power source connects to various components like the pump itself, the pressure switch, the control box, and any associated relays or capacitors. These diagrams are not just random lines and symbols; they are carefully designed to represent the flow of electricity and the function of each part. The ability to read and interpret a Well Pump Wiring Diagram is of paramount importance for both DIY enthusiasts and professional technicians.

These diagrams serve multiple purposes. For installation, they ensure that all connections are made correctly according to manufacturer specifications and electrical codes. During troubleshooting, a Well Pump Wiring Diagram acts as a roadmap to identify potential problems. For instance, if your pump isn't turning on, you can trace the wiring to see if power is reaching the switch, if the switch is functioning, and if the signal is making it to the pump. They can also be used to understand the role of specific components:

- Pressure Switch: This device turns the pump on and off based on the water pressure in your system.

- Control Box: Often found with submersible pumps, it houses starting capacitors and relays.

- Motor: The actual pump motor that draws water.

- Power Supply: The connection to your home's electrical service.

A typical residential well pump system might have a straightforward wiring configuration, but more complex setups, like those with multiple tanks or specific protection features, will have more intricate diagrams. Here's a simplified breakdown of what you might find:

- Power source (from breaker box) connects to the control box.

- The control box manages power delivery to the pump motor, often using a start capacitor to give the motor the initial jolt it needs.

- The pressure switch is wired in a way that it interrupts or allows power to the control box, thus controlling the pump's operation.

Understanding these connections, even at a basic level, empowers you to ask informed questions or perform simple checks before calling a professional, potentially saving time and money. For example, a simple visual inspection against the diagram might reveal a loose wire or a tripped breaker.

To gain a deeper understanding and to visually follow along with the explanations provided, it is highly recommended that you refer to the specific Well Pump Wiring Diagram that came with your well pump system or the documentation provided by your system's manufacturer.