Understanding the 6.0 Powerstroke Wiring Harnesses

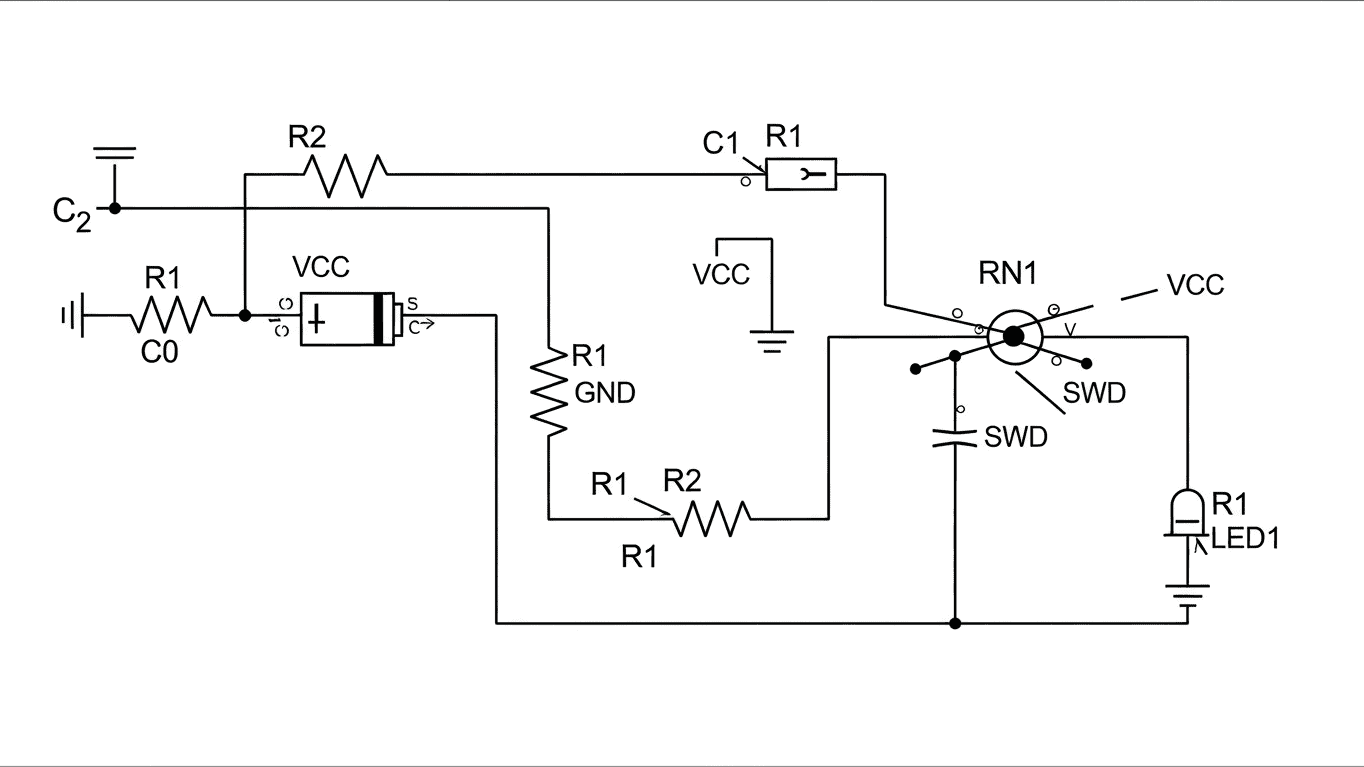

The electrical system of a 6.0 Powerstroke is complex, managed by a network of interconnected wiring harnesses. A Wiring Diagram 6.0 Powerstroke Wiring Harness Routing serves as a blueprint for these critical pathways. It visually represents the path each wire takes from its source, such as sensors or the engine control module (ECM), to its destination, which could be an actuator or another component. These diagrams are not just random lines; they are meticulously designed to ensure efficient and reliable power and signal delivery throughout the engine. The primary purpose of a Wiring Diagram 6.0 Powerstroke Wiring Harness Routing is to aid in diagnostics, repair, and installation. When a component fails or an electrical gremlin appears, the wiring diagram allows technicians to trace circuits, identify potential problem areas, and understand how different systems interact. This is incredibly useful for tasks such as:- Locating specific connectors

- Identifying wire colors and their functions

- Understanding continuity and voltage checks

- Identifying the symptoms of the issue.

- Consulting the wiring diagram to locate the relevant circuits.

- Performing voltage and resistance tests on specific wires and connectors.

- Following the harness path to pinpoint breaks or shorts.

| Harness Type | Typical Routing Path | Protection Measures |

|---|---|---|

| Engine Harness | Along the intake manifold, down towards the fuel injectors. | Wrapped in loom, secured with clips. |

| Sensor Harness | From various engine locations to the ECM. | Tucked away from hot exhaust components. |

For the most accurate and detailed information on Wiring Diagram 6.0 Powerstroke Wiring Harness Routing, please refer to your vehicle's official service manual. This will provide the definitive guide for your specific model year.