A VFD control wiring diagram is an essential blueprint for anyone working with variable frequency drives. This diagram visually represents how to connect the control circuits of a VFD, ensuring it operates safely and efficiently. Understanding the VFD control wiring diagram is crucial for proper installation, troubleshooting, and maintenance of motor control systems.

What is a VFD Control Wiring Diagram and How is it Used?

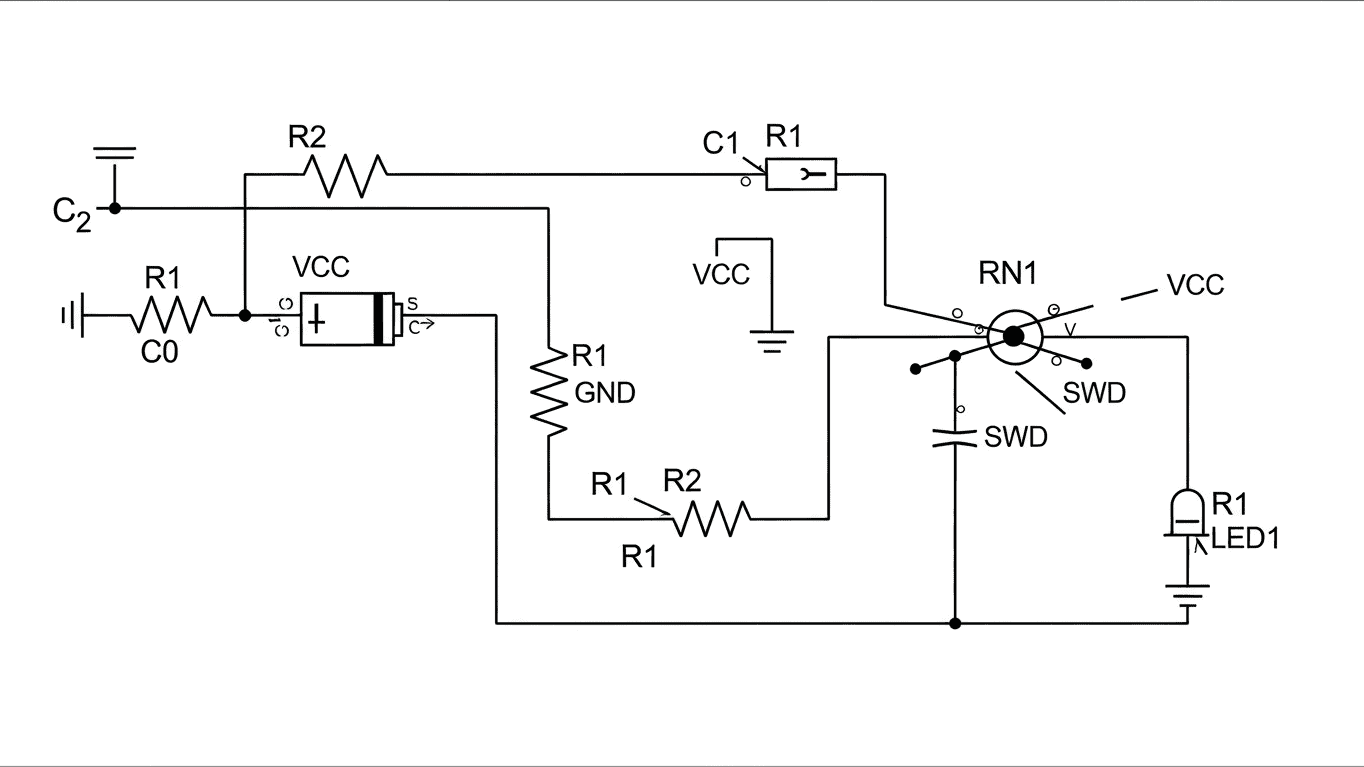

A VFD control wiring diagram is a schematic that details the electrical connections for the low-voltage control terminals of a Variable Frequency Drive. These terminals manage the VFD's operational commands, such as starting, stopping, speed adjustments, and receiving feedback signals. Think of it as the VFD's communication nerve center. The diagram outlines where to connect buttons, switches, potentiometers, relays, and sensors that tell the VFD what to do and how fast to run the connected motor. Without a clear VFD control wiring diagram, incorrect connections can lead to the VFD not functioning, damaging components, or even creating safety hazards.

These diagrams are indispensable tools for electricians, technicians, and engineers. They are used during the initial installation phase to ensure all control components are wired correctly. During troubleshooting, a VFD control wiring diagram is the first point of reference to diagnose why a VFD might not be responding to commands or is exhibiting unexpected behavior. Key elements typically found on a VFD control wiring diagram include:

- Power input terminals (for control power)

- Digital input terminals (for start/stop, forward/reverse, fault reset, etc.)

- Analog input terminals (for speed reference signals from potentiometers or PLCs)

- Digital output terminals (for indicating VFD status like running, fault, or at speed)

- Relay output terminals (often used for general fault or status indication)

- Communication terminals (for network connectivity)

The specific layout and terminal designations vary between VFD manufacturers and models, making it vital to consult the diagram specific to the VFD in use. A simplified example of how these might be presented is below:

| Terminal Name | Function | Typical Connection |

|---|---|---|

| DI1 | Digital Input 1 | Start Command (Momentary Pushbutton) |

| AI1 | Analog Input 1 | Speed Reference (Potentiometer Wiper) |

| DO1 | Digital Output 1 | Run Status Indicator |

The accuracy of these connections is paramount for the safe and effective operation of the motor control system.

When installing or troubleshooting a VFD, always refer to the specific VFD control wiring diagram provided by the manufacturer. This document contains the precise information needed to ensure correct and safe operation. The detailed instructions within this guide will help you navigate the complexities of VFD control wiring.