Understanding a Welder Plug Wiring Diagram is crucial for anyone working with welding equipment. These diagrams act as a roadmap, detailing how the electrical connections are made within the plug and receptacle of your welding machine. Whether you're setting up new equipment, troubleshooting an issue, or ensuring safe operation, a clear comprehension of the Welder Plug Wiring Diagram is your key to success.

Understanding Your Welder Plug Wiring Diagram

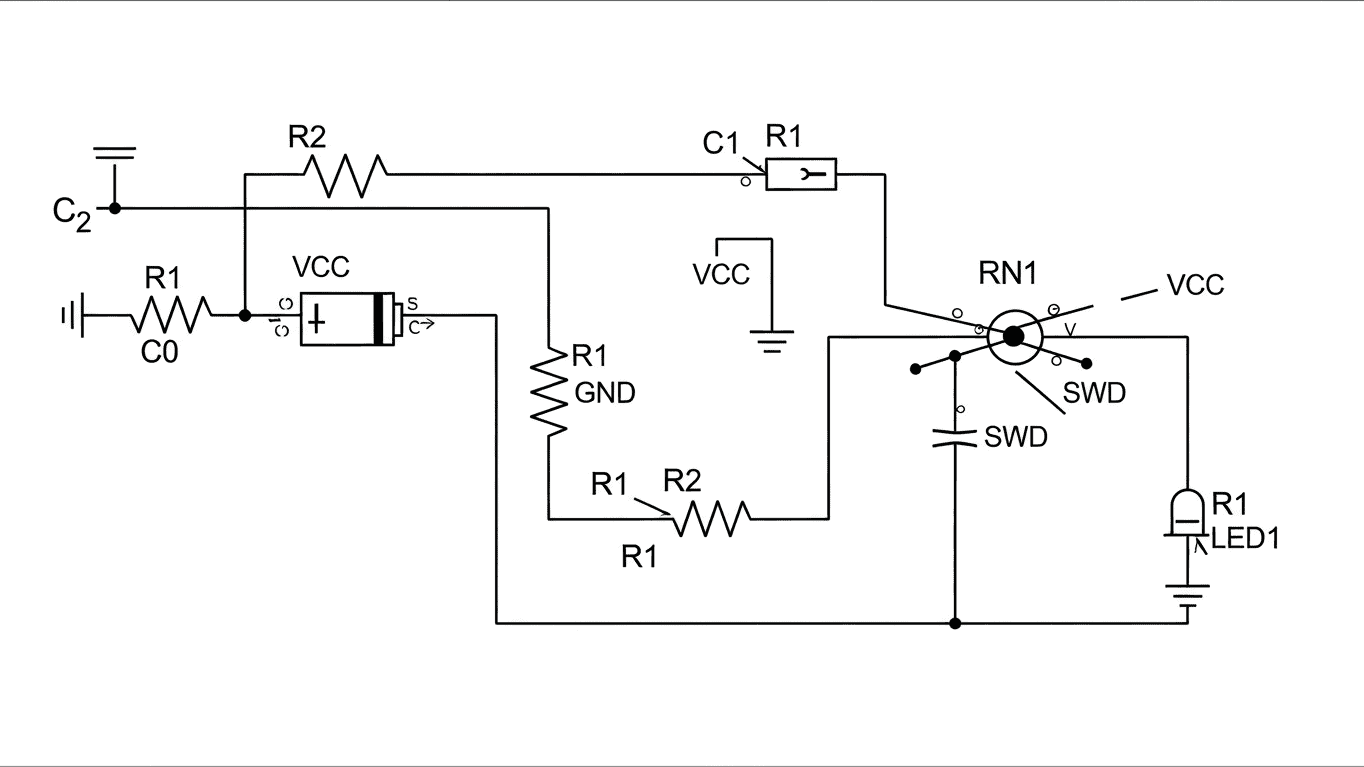

At its core, a Welder Plug Wiring Diagram illustrates the internal connections of a welding machine's power plug and its corresponding receptacle. It shows which wire connects to which terminal, ensuring that the correct voltage and amperage are supplied to the welder. This is not just a technical detail; it's fundamental for safe and efficient operation. Without a proper connection, your welder won't function, or worse, it could pose a serious electrical hazard. The diagram helps identify:

- The number of prongs (pins) on the plug and receptacle.

- The type of connection (e.g., straight blade, twist-lock).

- The intended purpose of each prong (e.g., hot wire, neutral wire, ground wire).

- The gauge of wire recommended for specific amperage ratings.

These diagrams are essential for several reasons. Firstly, they ensure correct polarity. Incorrect polarity can prevent the welder from operating correctly and can even damage the machine. Secondly, they facilitate proper grounding. A reliable ground connection is a vital safety feature, protecting users from electrical shock. Finally, understanding the diagram allows for correct plug and receptacle matching. Using the wrong type of plug or receptacle can lead to poor connections, overheating, and potential fire hazards. A typical setup might involve a grounding pin, one or two hot pins for different voltage inputs, and sometimes a neutral pin, depending on the welder's design and the available power supply.

| Common Plug Type | Typical Application | Number of Prongs |

|---|---|---|

| NEMA 6-50P | 240V Welders | 3 |

| NEMA 10-30P | Older 240V Welders (3-wire service) | 3 |

| NEMA 5-15P | Smaller 120V Welders | 3 |

To effectively use a Welder Plug Wiring Diagram, you need to cross-reference it with the specifications of your welding machine and the available power outlet. Always ensure that the plug on your welder is rated for the amperage and voltage it requires. If you're installing a new outlet or replacing a damaged plug, consulting the diagram is non-negotiable. It will guide you through the correct wiring sequence, ensuring all connections are secure and properly insulated. Remember, when in doubt, always refer to the manufacturer's documentation that accompanies your specific welder. The safety and functionality of your welding operation depend heavily on accurate and safe electrical connections.

For reliable information and step-by-step guidance on interpreting and using your Welder Plug Wiring Diagram, please refer to the comprehensive guide provided in the next section.